Sicherheitsschaltleisten für Industrietore, Fahrgasttüren und Arbeitsbühnen.

Flexibel kombinierbar, langlebig und von hoher Qualität.

Aktuell suchen wir:

Techniker / Ingenieur im Vertriebsinnendienst (m/w/d)

FEATURED

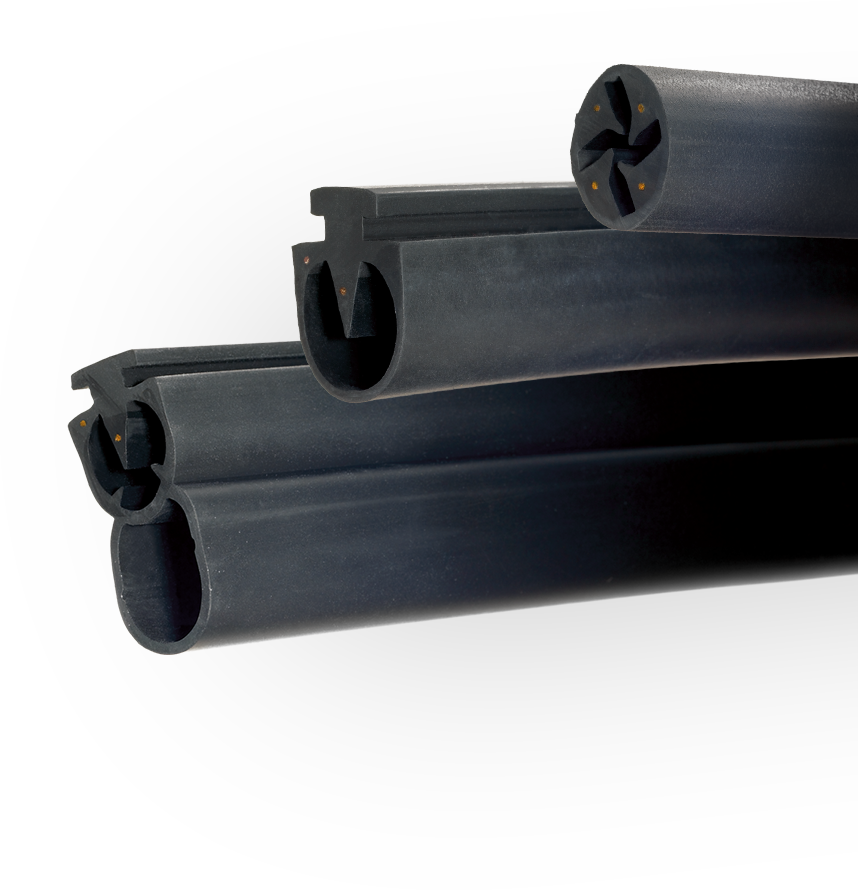

Contact-Optima-Profile

Für maximale Sicherheit sorgen höchste Empfindlichkeit durch vergrößerten Reaktionswinkel und integrierte Schaltung im Fuß.

- Max. Schaltempfindlichkeit bei seitlicher Betätigung ab einem Winkel von 180°

- Einfache, schnelle und sichere Konfektionierung

- Neuartige Optima-Plus-Verschraubung

UNTERNEHMEN